Oil Flushing

Oil Flushing

Oil system cleaning is performed during machinery overhauls with the objective and planned duration that allow time to clean the entire oil system. Typically, the used oil was removed from the reservoir, coolers, filters, and piping. The reservoir and filter housings were cleaned. New filters were installed. Jump-over or bypass oil piping was installed to bypass the bearing, seals, and gearboxes. All regulators and instrumentation were blocked in and bypassed to prevent damage during the flushing. The oil reservoir was then charged with new oil. The oil pump was started, and the oil was circulated through the oil system to clean out the system. Sound familiar? There have been many variations and iterations in these original flushing procedures. But the one common feature of these methods was that it was impossible to predict how long the process would take. And the economic impact of an unplanned, delayed start-up of a critical machine was very difficult to explain to management. Rather than reviewing the history of oil flushing, we will review what innovations have been developed to assure a successful, and timely oil flush.

Improvements in Oil Flow:

High and turbulent oil flow is one of the keys to success. Listed below are some of the proven methods to accomplish this.

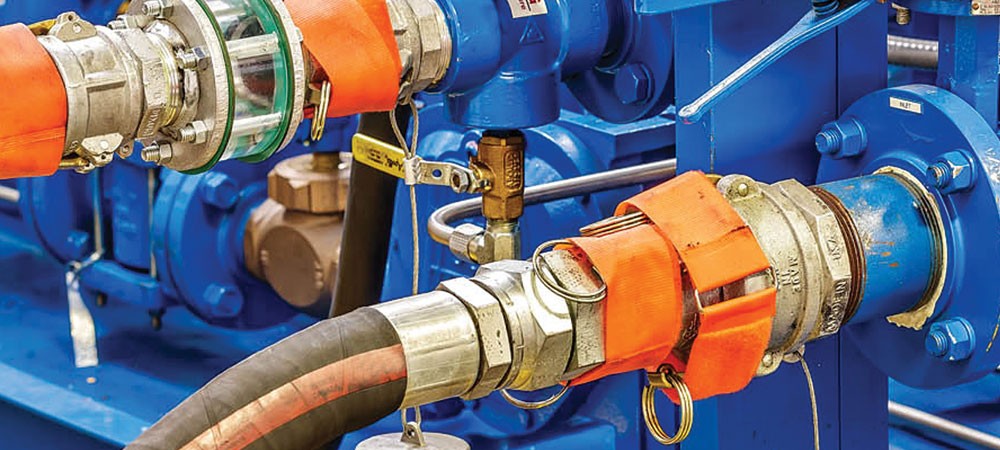

Eliminate restrictions in the flush system. Use hydraulic hoses with the minimum diameter of the oil supply piping for jump-over or bypass hoses.

Install 1/4 turn valves on each jump-over or bypass line to facilitate flushing one line or one system at a time to increase the flow.

The pumps used for oil flushing should be of higher capacity than the original pumps to increase the flow. If this is not possible, the jump-over or bypass valves can be used to flush one line or system at a time to increase flow. This will increase the time required to complete the flushing. Companies that specialize in oil system cleaning normally supply their own high-capacity pumps. High flow Air Operated Diaphragm Pumps (AODP), for example, works great in this application. Not only does the AODP supply the flow required, but the oil is also pulsating which causes turbulence in the flush system. The AODP can be obtained without the expense of using companies that specialize in oil system cleaning.

Nitrogen injection is used to produce turbulence in the flushing oil. Appropriate Nitrogen SAFETY PROCEDURES must be planned, effectively supervised, and carefully followed. The nitrogen injection point should be downstream of the filters and instrumentation that could be damaged by the turbulence. The nitrogen must be filtered before it is injected. The nitrogen should be injected ONLY when the flush oil is circulating. Only a small amount of nitrogen injected into the oil flush stream will cause the oil piping and bypass hoses to vibrate violently. Often the nitrogen injection is performed when the repair personnel are not present. If managed properly, the nitrogen injection is well worth the effort. We use the nitrogen injection only when the oil system is configured such that the pulsation from the AODP is attenuated.

Improvements in the Oil as a Flush Medium:

Originally, the same oil that was used during operation was used as flush oil. Listed below are some of the proven methods to accomplish this. Lighter-weight oil is preferred for flushing. If the normal oil is 30W oil, you would use a 20W or 10W to flush. Cleaning or detergent oil additives specially designed for oil system cleaning should be added to the flush oil. One example is Mobil System Cleaner. This detergent should be added to the flush oil according to the manufacturer's instructions.

When using lighter oils and detergents in the oil flush, it is very important to be sure to remove all the flush oil from the system before filling the system with the operating oil.

Improvements in Procedures:

In the typical procedure, the flush oil was heated and circulated until deemed clean. But in the final step of the procedure, the jump-over hoses were removed, and the oil piping was reinstalled with 100 mesh screens installed in the supply lines to all the bearings or seals. The oil was circulated for a given time, then shut down, and the screens were removed and inspected. Most of the time, I recall 100% of the time, the screens contained an unacceptable amount of foreign particulate. The screens were reinstalled, and oil circulation resumed. This was repeated until the screens contained an acceptable amount of foreign material. AND IT WAS IMPOSSIBLE TO FORECAST HOW LONG THIS FINAL STEP TO CLEAN WOULD TAKE. But why would an oil system that had been deemed CLEAN following the oil flush now be considered UNACCEPTABLE? The only changes were removing the flush hoses and installing the already clean oil pipe. The flow rate was much less due to the orifice effect of the bearings or seals. In our experience, the BIG change was the temperature cycling of the oil system. Listed below are some of the proven methods to take advantage of this important factor, along with several other important procedural details necessary to achieve a successful and predictable cleaning.

Cycling the flush oil system temperature is The key to success. The flush oil should be heated and circulated until the most remote oil flush piping skin temperature is at or near the temperature of the flush oil. While circulating, the flush oil should then be cooled and circulated until the flush oil and the most remote oil flush piping skin temperature is at or near the limitation of the oil cooling system. The heating and cooling cycle should be repeated until the flush oil cleanliness is deemed acceptable.

Heating the flush oil MUST be done with caution and safety in mind. Flush oil is normally heated to a minimum of 150F and to a maximum of 180F. Personnel protection must be considered for those working around the hot flush oil piping and all personnel must be aware of the possibility of hot oil leaks.

Heating and cooling the flush oil can have been achieved with the normal oil system coolers, but the procedure for using this equipment in an unusual manner must be carefully planned and implemented consistent with an organization's Management of Change procedures.

Cleanliness is a MUST in oil systems. Be sure that any item used in the oil flushing process is very clean. Piping gaskets have become a cleanliness problem since the spiral wound carbon-filled gaskets have become the gasket of choice. The carbon flakes get into the oil system and appear as foreign objects on the oil test screens, not to mention that carbon flakes may cause damage to the bearings or seals. We have had great success using class G4433 gaskets to maintain cleanliness.

The goal of oil flushing is to achieve a clean oil system in the allotted time. The procedures outlined above have been consistently successful in achieving those objectives. We have many years of planning and executing oil system cleaning. We also have more information on planning and executing machinery overhauls

OIL FLUSHING SERVICES

Flushing with lube oil is carried out to remove dirt from the system by loosening it from the inside of the system or by dissolving it in the flushing oil. Dirt that is picked up by the flushing oil will be caught in the fine mesh installed in the return line and can be removed.

This article contains an excerpt from the paper, Save your Centrifugal Machinery during Commissioning by Arun Kumar and Mohit Sabharwal of HPCL- Mittal Energy Ltd at the 2018 Asia Turbomachinery & Pump Symposia.

Before charging the lube oil inside the tank, it is important to ensure that the lube oil tank & run-down tank are thoroughly cleaned. All loose foreign materials such as scale, sand, weld splatter particles, and cutting chips shall be removed. The inside of the interconnecting piping should be wire brushed where accessible. Thereafter, the interconnecting piping shall be thoroughly cleaned before installation by air or steam blowing.

Lube Oil piping is to be connected and for initial flushing temporary bypass piping is to be connected for bearing housings and Seal Oil supply. The scheme is to be validated by the machinery OEM. Orifices, probes, and other flow restrictions must be removed for cleaning and flushing to obtain optimum velocities. All removed items shall be tagged and properly store for reinstallation. All the pressure gauges except the lube oil pump discharge pressure gauge, pressure switches, and instrument connections shall be isolated. All the PSVs shall be removed and blinded during the flushing.

Ensure Motor power connection is provided and, that the auxiliary and emergency oil pumps are ready for use to circulate lube oil. The entire lube oil circuit is divided into different circuits/loops to make the flushing more effective. Flushing of successive loops shall be started after the completion of the flushing of the preceding loop. Fill the tank with enough oil (up to min. level shown on the level gauge) i.e., up to the level such that the pump suction is fully immersed during flushing. Note that after starting the flushing oil, the level will drop inside the tank so the make-up oil arrangement should be ready. Ensure that the lube oil tank heater is commissioned and maintains a temperature between 60 70-degree C.

Make temporary hose connections / jump overs across the bearing housing as per the identified scheme connecting the supply lines to the return header with a fine mesh (100 mesh plain weave, stainless steel) in between. Install fine mesh (100 mesh plain weave, stainless steel) in the lube oil return line just before the tank as identified in the scheme. In the first circulation, filter elements should not be installed. Once the clarity of lube oil improves, filter elements should be installed properly seated in the filter housing. Ensure filter element commissioning spares are available. At the time of lube oil flushing through the bearing, the dry gas seal should not be in place but if it is already installed then a nitrogen/Instrument air purge shall be provided as a separate gas at design pressure.

Sufficient venting of the oil cooler & filters shall be done while taking inline to ensure no air pockets are left. Once the filter element is installed, periodically check the pressure drop across the oil filter. When the pressure drop becomes too high (As per OEM recommendation) change over to the clean filter element. Remove and replace the dirty filter element.

Initially, fine wire mesh should be checked after hr. of circulation for accumulation of dirt/corrosion products. Carry out the flushing of lube oil piping through the fine mesh into the return header for 12 hours for each loop. Periodically strike the piping to loosen any foreign material. Vary the oil temperature during the flushing process from hot to cold and vice versa several times. Stop the lube oil pump after 12 hours of circulation, allow for oil to drain back into the tank, and check the fine mesh for collected particles. Repeat flushing till no particles are observed visibly and no grittiness is felt by touch. The system shall be clean when the return line mesh is found to be free from any foreign particles.

A Centrifuge/online cleaning system shall be used for cleaning the lube oil in the reservoir during flushing. On the completion of the flushing, a lube oil sample shall be taken from the reservoir bottom and checked for water content and dirt contamination. Depending on the results oil shall be conditioned or replaced with fresh oil.

OIL FLUSHING SERVICES

The purpose of flushing is to remove contamination, which is either inherent or introduced during system assembly from the insides of pipes and components. Decontamination is accomplished by passing fluid through the system, usually at a velocity much higher than during normal operation.

Flushing is a vital procedure for the satisfactory operation and life of hydraulic and lubrication systems. If flushing is omitted or limited, it will inevitably lead to rapid wear on components, malfunction, and possible breakdown. Hydraulic and lubrication systems are very diverse, both in size and complexity. However, thanks to our many years of experience, EMBARK has designed and developed a wide program of flushing technologies, methods, and units, capable of meeting the ever-increasing requirements on cleanliness from component and system suppliers.

Proper oil flushing of rotating equipment tends to be an afterthought. Whether it is commissioning or maintenance involving end users, construction groups, or manufacturers, oil flushing tends to be thought of as a "just do it" item.

The only time it becomes a priority is when a system fails, and then it is all about getting back online quickly and not so much about planning. Fortunately, there is a better way. The following six steps are intended to help you achieve a more successful high-velocity oil flush.