Hydro Jetting & Hydro Blasting

Hydro Jetting & Hydro Blasting

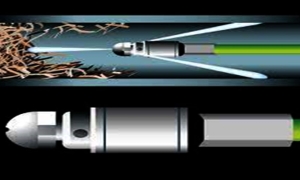

Hydro Jetting or Hydro Blasting is a method of cleaning out pipes, tanks, and surfaces (power

washing) that involve pumping high-pressure water over the pipe. Using 4,000psi water

sprays, this process will blast through any blockages that are in the drainpipe. The

benefits of using the hydro Jetting method are that they clear the entire diameter of the

pipe and that they can be used in a variety of settings without damaging your

plumbing.

When used in a larger pipe setting, these hydro jet pumps use nozzles

that spin to get greater coverage of the pipe and tank. They can rotate at speeds up to

10,000 rpm, completely clearing the pipes and tank of grime while unblocking them.

High-pressure hydro blasting: Pressures from 690 bar (10,000 psi) to 1,700 bar (25,000 psi).

- Ultra-high-pressure hydro blasting: Pressures of more than 1,700 bar (25,000 psi). We have up to (35,000 psi).

- Up to 35,000 psi

- Machines with all types of accessories

- Rental / Leasing

- High-pressure hydro blasting: Pressures from 690 bar (10,000 psi) to 1,700 bar (25,000 psi).

- Ultra-high-pressure hydro blasting: Pressures of more than 1,700 bar (25,000 psi). We have up to (35,000 psi).

- Up to 35,000 psi

- Machines with all types of accessories

- Rental / Leasing

HYDRO JETTING & HYDRO BLASTING SERVICES

Hydro-Jetting, also known as retro-jetting or hydro-milling, is an efficient method of cleaning industrial piping through the implementation of high-pressure water nozzles and jets.

Newly installed process piping typically contains exuberant amounts of foreign debris. These residual deposits can potentially compromise system reliability and lead to premature system degradation and catastrophic failure during plant operation. To help preserve the long-term integrity of these process piping systems, hydro-milling can be used to remove all undesirable foreign contaminants and particulate matter.

Hydro-milling has been proven as an effective means of removing both large and fine debris from piping surfaces, including post-construction debris, by-products that result during fabrication, and operation-derived deposits, which are comprised of welding slag, mill-scale, loose rust, and mineral sediment.

When compared to more traditional water flushes, hydro-jetting can match or exceed cleanliness specifications while reducing the time and costs associated with water, waste disposal, scheduling, and equipment requirements.

Hydro jetting encompasses a process that relies on using pressurized water to clear pipes. Experts push the high-pressure water through your pipes using a special hydro jetting machine.

This process rids the interior of the pipe from built-up debris that has triggered a clog or slower flow. In cases of grease build-up, hot water is often used for additional effectiveness in resolving the drain clog.

Before the hydro jetting, most drain cleaning services would rely on rodding that involved using a tool such as an auger to pierce the debris in a bid to open up the water flow. This is still a common method and works for smaller clogs.

Hydro jetting is considerably more efficient in clearing the build-up and reducing the chance of recurring clogs. Once a qualified plumber pinpoints the ideal problem area to pump the water, they will insert a hose that is tied to a large water tank or water line. Depending on your clog's nature and severity, the plumber will select a pressure level to use.

Hydro jetting can shoot a maximum of 20 gallons of water per minute (5000 psi) through your sewer pipes. With most of the piping angling downward from your home into the sewer line, the dislodged material causing the clogging will flow down into the sewer system.

Hydro jetting can take care of a broad range of materials. It will also clear the build-up of hair, tree roots, minerals, food, grease, and soap. Afterward, the pipe wall can be so clean it looks brand new.

Other alternatives to hydro jet drain cleaning include using tools such as plumbing snakes and augers. These still work on minor problems, but these are not as effective as hydro jetting. Additionally, they sometimes only temporarily release the pipe blockage as opposed to curbing blockages in the future. They can also push the waste deeper into the plumbing lines, making a bad situation worse.

The hydro jetting process is required when the main line system is impaired with severe, recurrent clogs. The insides of pipes usually scale up with grease or mineral build-up, and debris. These cause slow draining and eventually lead to clogging.

When this problem gets beyond the reach of many local drain cleaning services it can even trigger sewer backups. If the plumbing system blocks up entirely, dirty water may find its way into your home.

Fortunately, you do not have to resign yourself to this fate. Hydro jetting solves these drainage problems by pumping high-pressure water into the pipes. The hot water jet system uses the force of gravity to clear up the pipes.

The tell-tale sign that hydro jetting is the best fit for your home is a smelly sewer drain that repetitively clogs up. A plumber can assist in eradicating the obstructions in your pipes, even if they are present in the yard, allowing you to live peacefully.

An experienced plumbing service that uses camera inspection will give insight into whether hydro jetting is the right solution.

HYDRO BLASTING

Hydro blasting is the method of cleaning the surface of various materials (e.g., steel, stone, cement, plastic, and wood) through a jet of water from a special tool gun with extreme pressure. This process provides an excellent bonding surface for material repair and new coating applications. Moreover, it relies entirely on the energy of water striking a surface to achieve its cleaning effect with no abrasive materials being involved. Consequently, with the problems of dust pollution and disposal of abrasives eliminated, we have an environmental-friendly alternative to sandblasting.

Depending on the pressure range utilized, hydro blasting is distinguished into four main categories:

- LOW-PRESSURE WATER CLEANING - LPWC

Low-pressure water cleaning refers to a water pressure of less than 340 bar (&It;5000 psi) and its aim is the removal of marine organisms and loose pieces of rust or paint, dirt, and salt before applying the main cleaning process. It is not considered to be a method of pre-preparation before the main cleaning method is applied.

2. HIGH-PRESSURE WATER CLEANING - HPWC

High-pressure water cleaning refers to water pressure between 340 and 680 bar (5000 10000 psi). With this pressure loose rust and paint in the hollows of the surface can be removed but cannot achieve a uniform matte appearance.

Its applications are:

- Removal of marine organisms from the hulls, which are not removed by low-pressure water jets.

- Selectively remove layers of paint.

- Light cleaning of rust and paint.

3. HIGH-PRESSURE WATER JETTING - HPWJ

High-pressure water jetting refers to water pressure between 680 and 1700 bar (10000 - 25000 psi). In practice, high-pressure water jetting can perform most tasks of cleaning and preparation of surfaces encountered in ship-repairing, ship-building, or industrial environments.

4. ULTRA-HIGH PRESSURE WATER JETTING - UHPWJ

Ultra-high pressure water jetting refers to water pressures above 1700 and up to 3000 bar (25000 - 43500 psi). Some of the latest marine coatings require surface preparation up to this level to achieve the bare metal result or locally at some extreme cases when paintings with very strong adhesion, deep rust, or calamine are encountered. Our company's latest technology equipment covers this service both via guns/operators and spider machines.