Piping & Structural Fabrication & Erection

Piping & Structural Fabrication & Erection

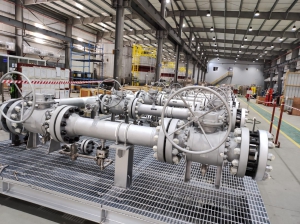

The piping process requires several considerations to ensure the piping efficiently and safely transports raw materials. Constructing a process piping system typically involves:

- Pipe routing design and implementation. The piping system should be designed to efficiently route materials to the necessary locations. It also requires the proper implementation of pipes and components.

- Pipe design support and installation. Work with an experienced company that can provide design support and installation services for your process piping system.

- Piping and instrumentation diagram (P&ID) development and implementation. A P&ID maps the various piping and components that are present in your process piping flow process. This provides a graphic representation of your system's details, schematics, and more.

- Pipe material selection. Choose the best construction materials for your process piping system based on the type of materials it will be transporting.

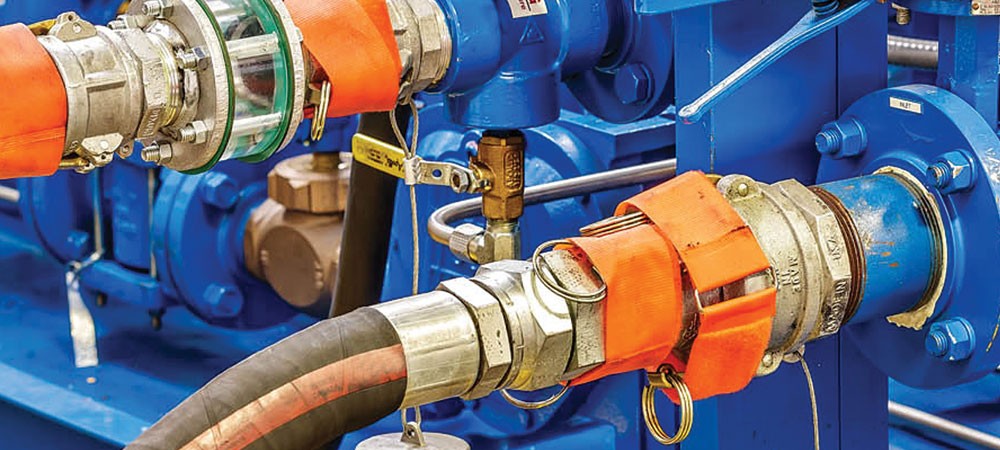

- Manual and control valve selection. Control valves and manual valves are also crucial components for regulating pressures and flow in the process piping system.

- Pipe installation. To ensure optimal effectiveness and efficiency, work with a partner that has extensive experience in installing these systems.

- Pipe testing. The piping must undergo rigorous testing for safety and functionality.

- Pipe painting and labeling. Painting and labeling are crucial for indicating and differentiating the differing piping throughout your system.

- Pipe insulation and heat tracing. Insulation or heat tracing may be necessary to keep the piping and its contents at a specific temperature.

At Base Construction, we can provide all of the above-mentioned services to ensure the best possible process piping system for your facility.

PIPING & STRUCTURAL FABRICATION & ERECTION

The structural fabrication process involves multiple stages. This process requires skilled and experienced technicians who can take raw components and transform them into quality products. Each of the processes is discussed below.

Stage 1 Ideation, blueprint, and shop drawings

The ideation stage can be creative as per the requirement of using steel components. Here the fabricator can make any structural steel products that you are looking for. Blueprint: Drawing is created through different software which undertakes requirements, code compliances, and specifications. Conversion of Blueprint into Shop Drawings. To complete the processing of steel it will be converted into shop drawings that will adhere to the logistics of the project including deadlines and budget.

Structural steel fabrication involves cutting, bending, and welding steel to make a structure. Unlike various types of welding in which steel alloy is repaired or strengthened, steel fabrication is when pieces of steel are put together to form different structures that are usually of predefined sizes and shapes. This process requires skilled and experienced technicians who can take raw components and transform them into marketable products hence not everyone is capable of fabricating structural steel.

Stage 2 Cutting, bending, and drilling

Cutting is the first part of structural steel fabrication. High-grade steel needs to be cut by cropping or sawing using different tools like laser cutters, plasma torches, water jets, etc. This is usually done in a closed manufacturing factory and some safety measures are needed to be taken for this process. The methods typically employed are sawing (cold sawing or band sawing), burning, and shearing. Shearing generally is limited to miscellaneous structural steel parts. It is not used on larger structural elements, because the force required and the resulting cut quality limit economic and practical feasibility.

Bending comes next. The bending of the structural alloy for which there is specialized machinery; there are still many fabricators who prefer to do it manually by hammering the alloy as well. It also depends on the type of project as, if there is a requirement for a repetitive bending of multiple sheets of steel, then using machinery will be much more feasible. ! There are five typical methods of bending in the industry: rolling, incremental bending, hot bending, rotary-draw bending, and induction bending. Each method has its advantages. The principal advantage of curved structural steel is its aesthetic appeal. It allows architects and designers to express a variety of forms and makes exposed steelwork an attractive solution.

Third comes welding. It involves creating a variety of welds with different component materials to create, fabricate, and erect welded structures. Seal sections are assembled here to make complete structures. After the cutting and forming of steel components are done, then the welding process begins to assemble it into a complete structure. Structural welding has its own set of codes, blueprints, and types of weld joints. It is used to create metal frameworks for buildings, bridges, vehicles, and a variety of other complex structures. Structural welding is also used to cut and repair beams, columns, and girders.

The Regular Steel fabrication elements are Plate Metal, Formed, and expanded metal, and Welding Wire/ Rod Casting.

Stage 3 Engraving and assembly

All the steel items will be etched with part numbers and plate locations that convert it into a final assembled part on-site that is fast, easy, and accurate. The component assembly is an integral part of the steel fabrication process. It is required to attach fixtures and fittings to prepare connections for installation on site. Steel sections are assembled here to make complete structures. Once the assembly of components is finished, it will be checked if it meets the specification or not. Fabricators sometimes create custom parts that are ideal when you need components to fit a structure or product used in your project.

Stage 4 Shipping preparation and component finishing

In this stage, all the assembled components are packed to make the project erection at the site easy. Once the steel is completely assembled into the shape that we were looking for it is then processed for applying the coating to protect it against corrosion and fire.

Stage 5 Site delivery and erection

The final shipment of the components is done in this stage. The project is then erected on the site for construction purposes.

PIPING & STRUCTURAL FABRICATION & ERECTION SERVICES

Once the design is completed and all approvals granted, the normal pipeline construction process is as follows:

- 1. LANDHOLDER ENGAGEMENT AND ACCESS APPROVALS:

Meetings are held with affected landholders to discuss and agree on access to their properties during pipeline construction and ongoing operation.

- 2. SURVEY AND FENCING:

The pipeline route is surveyed and fencing is modified to facilitate access during construction.

- 3. CLEAR AND GRADE:

Graders, bulldozers, and excavators are generally used to clear and prepare the easement ready for construction to commence. Topsoil and vegetation are stockpiled separately to assist in restoration works after the pipeline is completed.

- 4. STRINGING:

The pipe is transported into the easement and laid end to end next to where the trench will be dug.

- 5. BENDING:

Where required, specialized machinery is used to bend the pipe to conform with the contours of the land and the pipeline route.

- 6. WELDING AND NON-DESTRUCTIVE TESTING:

Pipe sections are welded together. All welding is tested to ensure quality.

- 7. JOINT COATING:

The areas of the weld are cleaned and pipe joints are coated to reduce the possibility of corrosion.

- 8. TRENCHING:

Specialized trenching machines and excavators are used to dig the trench.

- 9. LOWERING IN AND PADDING:

Specialist equipment (side booms) is used to lower the pipe into the trench. The pipe is then covered by fine-grain material (padding) to protect the pipeline coating from stones or other sharp objects.

10. BACKFILLING:

The trench is backfilled with the previously excavated subsoil material. Care is taken to maintain separation between topsoil from subsoil during this process. The subsoils are compacted to limit the settlement of the trench through the operational life of the pipeline.

11. HYDROSTATIC TESTING:

Using water, the pipe is pressure tested (hydro tested) to ensure it is fit for operational service.

- RESTORATION AND SIGNAGE:

Disturbed areas are reinstated to match existing landforms which include re-contouring and installation of permanent erosion control structures. Topsoil conserved during the construction process is respread over areas used for construction. Rehabilitation is undertaken in accordance with approval requirements and landholder considerations. Signs are placed at regular intervals and with line-of-sight of one another to indicate the presence of the buried pipeline.