Chemical Cleaning

Chemical Cleaning

To remove a wide range of deposits and scales with different chemical combinations that have an industrial origin, we utilize the most recent chemical cleaning technology. In order to fulfill the exact cleaning demand, we collaborate with the client. To provide the best solution and achieve the highest level of client satisfaction, we evaluate the scales or deposits in our laboratory. With the aid of a variety of large resources, such as circulation systems, boilers, portable heat exchangers, circulation tanks, effluent storage tanks, etc., we can undertake significant chemical cleaning projects. We also adhere to safe environmental practices when handling and disposing of all spent chemicals in accordance with client and governmental requirements.

Our approach to a safe and quality cleaning process entrusted by the following steps:

- Choosing the right chemistries depends on metallurgy scales preservation schedules.

- Choosing the right equipment like pumps, temporary piping, fittings, etc. depending on circuit flow, flow restriction, pressure drops, velocities, and other parameters.

- Choosing reliable Laboratory monitoring facilities for right control by monitoring parameters during cleaning for proven results.

Chemical Cleaning is the procedure for field cleaning of the piping systems especially Steam lines inlet for Turbines and Steam Drums. These pipelines after cleaning shall be free from hydrocarbons, greases, oils, rust, scale, and other impurities. In Chemical cleaning, chemicals are used to dissolve or loosen the hard deposits from process equipment or piping surfaces and removed them.

Most of the steam systems have carbon steel pipelines which will have a lot of rust, welding spatters, and slags inside during the construction. The chemical cleaning will reduce the duration of Steam lines flushing by 1/3rd of the actual duration. This will reduce the Project schedule and improve the quality inside the pipelines.

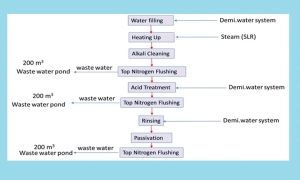

The whole chemical cleaning procedure can be parted into the following steps:

- Erection and installation of temporary equipment such as:

- Circulation pump

- Chemical injection pump, chemical dissolving tank, and ejector

- Steam mixing heater

- Hydrazine injection system

- Waste neutralizing tank and wastewater pump

- Temporary piping between tie-in points on the permanent facility and temporary equipment. (For the purpose of by-pass, circulation, and so on)

- Installation of solution recovery line onto drain and vent by a rubber hose.

- Blind plates shall be inserted at safety valves and non-necessary items.

- Installation of the restrictive orifice on the system.

- Line/valve check of the system to be cleaned including temporary piping.

- Utility piping from the supply point to the cleaning system.

CHEMICAL CLEANING SERVICES

There are pipelines that need extra treatment to achieve the desired result. During the pigging of pipelines, bypass can occur. This way some product will be left inside the pipe. The product that is left behind can evaporate and cause gas concentrations that rise above the Lower Explosion Limit (LEL). This can lead to dangerous situations during maintenance work. Chemicals can bind the hydrocarbon molecules and keep the pipeline in a safer condition.

Chemicals can also help during the testing and preservation of your pipeline which limits corrosion. Most pipes are tested with water, but if the outside temperature is below zero, testing with only water is not an option. Depending on the available time, TECCURO can, in consultation with you, add a chemical to prevent the water from freezing. TECCURO's chemicals can also cause the water to be treated, for example during testing and pigging to significantly slow down the corrosion process in pipes that are difficult to dry

Chemical Cleaning will be done to remove the storage and assembly rusting, protective greases and oil, mill scale, welding slag, dust, dirt, scale, and most protective coatings from pipes and other atmospheric or contact erection residue. After completion of chemical cleaning and restoration, CS pipes will be preserved/filled with nitrogen gas to avoid further rusting.

Physical residues like welding rods, bolts, nuts, brooms, spades, helmets, boots, sleeping fitters, etc. must be removed mechanically prior to chemical cleaning.

The items will be identified as per the given pipes and compared to the piping & instrumentation diagram (P&ID). The volume will be calculated as per actual dimensions and the given isometric drawings. The extra volume will be added since we must add the volume for our temporary hoses and mixing tanks. Total volume is the actual value for the pipelines plus the temporary equipment & hoses volume will be the working volume on which our calculation will be based (Chemical amounts. Timing. etc)

The cleaning is done by circulation of the acid solution. The solution will be suitably heated and diluted chemical water is circulated through the concerned part of the piping system for proper mixing. The heat source is suitably selected according to site availability. The cleaning will generally be carried out system-wise as appropriate and depending on the erection schedule (Completeness of the systems).

CHEMICAL CLEANING SERVICES

EMBARK provides professional chemical cleaning services to all segments of the industry. We clean virtually everything from large steam boilers to the smallest heat exchangers.

EMBARK welcomes the challenge to analyze your fouling problems, developing solutions, and proving the economical advantages of its working methods. Every project does require a careful study of the existing problem. Analysis of equipment and deposits, to select the right solvents and cleaning techniques, will be made. Before a job starts, you know in writing what you will get for your money. EMBARK provides a complete chemical cleaning service.

EMBARK analyses the scale and designs a process tailor-made to your requirements, then the crew of skilled supervisors, chemicals,s and technicians, are deputed to the site. Pumps, tanks, trucks, chemicals, and any required special equipment to the job site. The project is completed to satisfaction with strict adherence to safety and environmental regulations.