Cold cutting ECO

Cold cutting ECO

Cutting system ECO TOP Cutter 3000

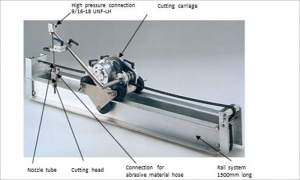

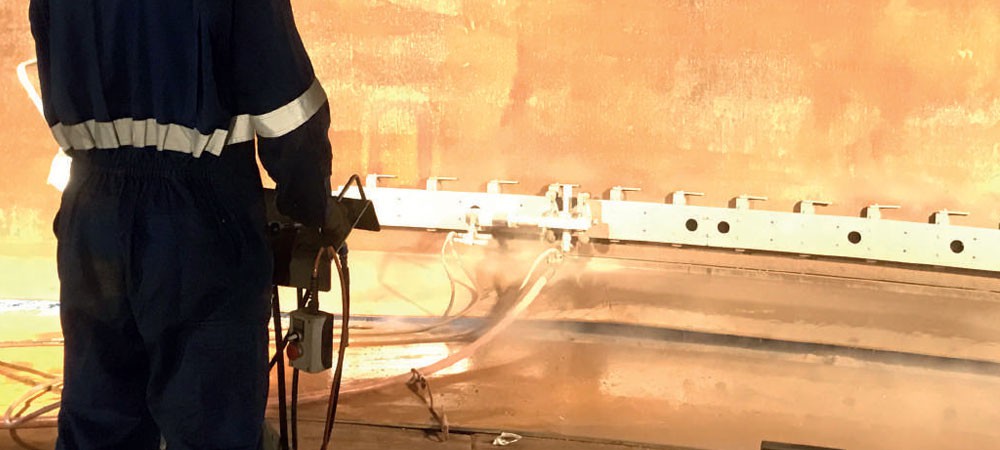

With the cutting system ECO TOP Cutter ETC 3000 round (-R), as well as linear (-L) cuts, can be done effortlessly. Depending on the type of material to be machined (e.g. concrete or steel) and the required cutting depth, the system is offered with two different speeds (slow ... -L and fast ... -S).

A special system variant (... -P) is available for precision round cutting with a circular accuracy of approx. 0.5 mm with diameters of 800 to 1,400 mm.

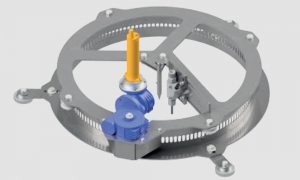

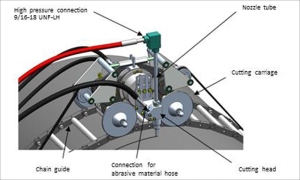

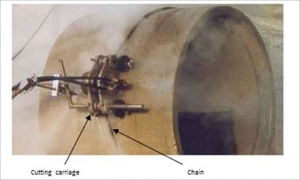

The cutting carriage with the attached cutting head is driven by an air motor and follows a guide chain in the case of round cutting and a guide rail in the case of linear cutting.

The water is fed to the cutting head under high pressure via the nozzle tube and produces a vacuum in the vortex chamber of the cutting head, which sucks the abrasive material and admixes the high-pressure water (injector principle).

With the ECO TOP Cutter 3000 system, composite materials or material combinations can also be separated in one cutting cut without causing any thermal or mechanical stresses at the cutting edges.

Furthermore, extensive accessories enable the application-specific expansion and adaptation of the cutting system to the most diverse application requirements.