Turnaround Services

Turnaround Services

All the tools are on hand at EMBARK to do the turnaround and shutdown work. One of the strengths of EMBARK is its dedication to finishing projects on schedule. We stand out from the competition thanks to our knowledgeable and talented turnaround planning, management, and execution teams.

Our turnaround management strategy considers pre-engineering necessities like scheduling, estimating, planning, task force orientation, etc. to help our customers reduce expensive downtime. These aid in distinguishing between critical and non-critical jobs, improving overall accuracy for meeting completion goals.

TURNAROUND SERVICES

In maintenance, a turnaround is an event where one or more assets are temporarily removed from service so that maintenance tasks can be performed. While specific turnaround procedures may differ across various plants and industries, five main phases are usually observed:

- Definition/Scoping

- Preparation

- Execution

- Start-up/Turnover

- Evaluation

Phase 1: Definition/Scoping

Turnaround maintenance procedures are expected downtime events with anticipated durations. However, although they are expected, turnarounds still cause long periods of stopped operations. Therefore, they inherently incur losses in production. This highlights the importance of a well-planned turnaround to ensure that the time lost is spent efficiently.

In the definition and scoping phase, maintenance teams create a list of activities that will be performed on assets. For example, assets might be scheduled to undergo one or more of the following activities performance tests, component replacements, repairs, or standby.

The output of turnaround maintenance at this phase is a work list that details the exact activities to be performed on specific assets. A computerized maintenance management system (CMMS) is the best tool you can use to keep track of your turnaround work list.

Phase 2: Preparation

Now that a work list is available, the team can start the preparation phase by identifying what resources they will need to cover the scheduled activities. Preparation includes any material resources required, as well as knowledge and training needed for staff to perform all tasks. Staffing requirements are also important to consider. Depending on the decision of the management team, tasks can be assigned to internal or external personnel.

Aside from material and staffing resources, this phase also accounts for safety requirements and procedures that need to be checked. Some maintenance activities would require special handling to reduce risks and avoid unexpected incidents.

Phase 3: Execution

The execution phase immediately begins with the stoppage of the equipment. Most tasks in this phase involve some form of inspection, corrective action, and testing. Tasks are then updated and removed from the identified work list (from Phase 1) as they are completed. The progress of this phase can effectively track using the CMMS.

Phase 4: Start-up/Turnover

The next phase is the start-up or turnover phase. This is both an extension of the execution phase and the transition back to normal operations.

After all tasks in the work list have been performed and the final tests passed, the start-up can then begin. The start-up phase is essentially an operational state but done while being closely monitored by the support groups. When satisfactory conditions are met during the start-up, ramp-up can begin. Ramp-up is the gradual process of bringing the facility back to normal running conditions. It is a crucial period that minimizes the risk of any incidents.

Phase 5: Evaluation

Lastly, the evaluation phase reconciles all tasks that have been performed. This process accounts for all costs incurred from the turnaround process and looks back to confirm that all work orders and purchase orders have been closed. Any material stock that has been left over can then be credited back for future use.

An audit is usually conducted at this phase to assess the state of each asset. Any actions identified from the turnaround procedure are also listed at this stage and delegated to the accountable units within the team. The final collection of data and observations provides insights into the plant's safety, efficiency, performance metrics, and overall performance.

TURNAROUND SERVICES

Turnarounds are some of the most essential times in refineries and other process plants but are also responsible for massive portions of a facility inspection and maintenance budget.

Turnarounds that run over budget or over schedule have wide-ranging, damaging implications for refineries. These problems can be exacerbated by the need to have multiple, competing on-site teams to complete all the planning, inspection, and maintenance work necessary to get a plant up and running at peak capacity.

EMBARK simplifies the turnaround process by designing, managing, and executing all aspects of your turnarounds from planning to engineering to inspections to maintenance, with the convenience of a single contractor.

We develop turnaround inspection and maintenance plans designed to address maximizing safety practices, minimize environmental hazards, and ensure each client is in compliance with legislative and regulatory standards.

EMBARK designs and executes turnaround programs with a few core objectives:

- Reduce maintenance costs

- Reduce downtime by shortening T/A duration

- Extend run length between shutdowns and T/As

- Improve safety and overall reliability

Among others, EMBARK offers API 510, 570, and 653 inspection services for assets and facilities throughout the oil & gas, petrochemical, and process industries. With an expansive technician base located all over the world, we can conduct inspections and perform engineering reviews for any local, federal, or governmental regulations.

API Turnaround Planning Consultations

The goal of turnaround planning is to ensure that plant and refinery inspections are completed as safely and efficiently as possible and that any necessary inspections are prioritized and performed about historical equipment data and known damage mechanisms.

EMBARK helps our clients meet these objectives by offering dedicated engineers with decades of experience in anticipating damage mechanisms and developing targeted turnaround execution plans.

Our Turnaround Planning teams pride themselves on individually developing the most effective inspection test plan for each client. Starting up to a year before the planned turnaround, we conduct inspections to identify existing problem areas and review past inspection histories and trends to pin down issues that are likely to re-occur. This is a necessary step because unanticipated damages are often the culprit of turnarounds going over budget and over-schedule.

As the turnaround execution plan takes shape, we work with our clients to:

- Define the major inspection discovery work that will be required during the shutdown

- Anticipate mechanical repairs that may arise during the discovery process

- Establish objectives and milestones

- Navigate any organizational or situational barriers.

Refinery Turnaround Inspection Services

Once the turnaround begins, we provide high-quality non-destructive testing (NDT) inspection services for all refinery assets, including:

- Piping

- Storage Tanks

- Rotating Equipment

- Pressure Vessels

- Valves

To adapt our inspection plans to each client's specific needs, we deploy technologies and make use of a wide variety of traditional and advanced non-destructive testing (NDT) inspection techniques, including, but not limited to:

- Acoustic Emission (AE)

- Automated Ultrasonic Testing (AUT)

- Eddy Current (EC)

- Magnetic Particle Testing (MT)

- Penetrant Testing (PT)

- Radiographic Testing (RT)

- Ultrasonic (UT)

- Visual Testing (VT)

API 510 Inspections for Pressure Vessels

EMBARK has gained an extensive wealth of experience planning and performing API 510 inspection services for in-service pressure vessels, deploying a wide array of solutions to identify signs of internal and external corrosion, erosion, cracking, weld flaws, wall thinning, and other metallurgical discontinuities.

Adhering to API 510 guidelines during turnarounds, EMBARK performs Fitness-For-Service (FFS), Probability of Failure (POF), and rate of corrosion calculations to ensure pressure vessels remain in-service, in-market, and without risks of damage to both physical and human assets.

API 570 Inspections for Piping Circuits

EMBARK Group adheres to the specified guidelines of API 570 for the inspection and maintenance of in-service piping circuits and pipelines in oil & gas and petrochemical facilities.

EMBARK ensures piping systems operate in compliance with mechanical integrity (MI) guidelines.

API 653 Inspections for Aboveground Storage Tanks

EMBARK API 653 turnaround inspection services are designed to help refinery aboveground storage tank (AST) operators identify signs of damage including corrosion, leakage, cracking, and wall-thinning.

EMBARK-trained and certified turnaround API inspectors help you achieve API 653 compliancy by conducting on-site, non-intrusive inspections to the tank outer shell, tank floor, annular ring, and roof, without the expense of entering, draining, or shutting down a tank.

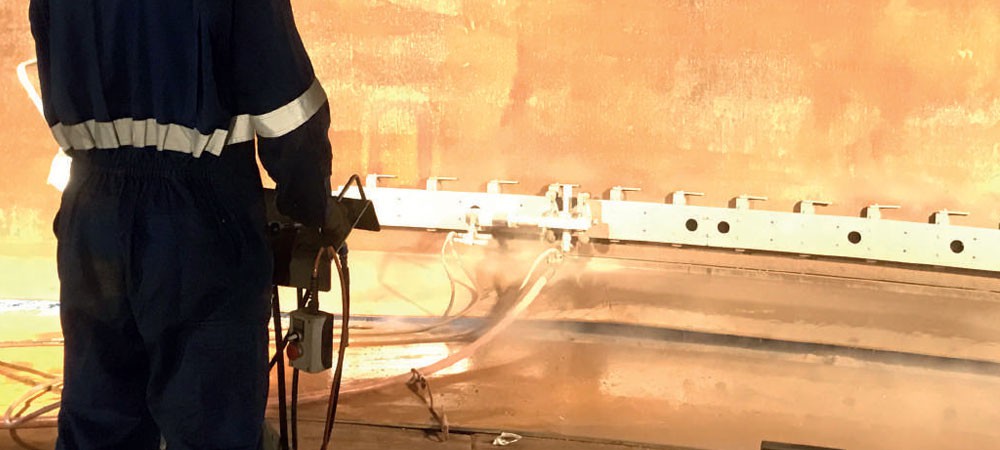

Turnaround Maintenance Services

EMBARK offers multi-disciplined technicians that are often able to repair minor damages found during the inspection process.

By utilizing rope access technicians, we can inspect and repair at-height assets without the use of scaffolding, enhancing safety by reducing on-site equipment footprint.

During turnarounds, EMBARK performs:

- Corrosion Removal and Mitigation Services

- Insulation Stripping and Installation Services

- Industrial Cleaning Services

Turnaround Inspection Data Reporting

At the conclusion of the turnaround process, EMBARK produces a comprehensive inspection report for each piece of equipment involved in the turnaround.

These reports detail the inspection results and the work that was completed, inform the client of any anticipated work to be expected at the next service interval, and recommend solutions moving forward.

Clients can then use these reports for both the immediate and long-term management of their key operating assets.