Bolt Torquing & Tensioning

Bolt Torquing & Tensioning

Bolt torquing and bolt tensioning are two different ways to stretch and put a load on a stud, and achieving an accurate load is necessary to prevent leaks. Torquing generates load by turning a nut on a helical thread, and it is the more common but less accurate method for achieving bolt load. This decrease in accuracy increases the risk of leaks, presenting the biggest pitfall of torquing, but there are more. Torquing cannot prevent galling, which can bring breakouts to a halt, causing project creep and unpredictable labor costs. Furthermore, torquing increases the risk of hand injuries by creating pinch points, reducing worker safety. While there are some scenarios where torquing is preferable to tensioning.

such as working with short grip length, thin flanges which might bend under heavy loads, or short stud length on top of the nut where studs cannot be changed due to blind holes for most other applications, tensioning is the more accurate, faster, and safer method for achieving optimal load.

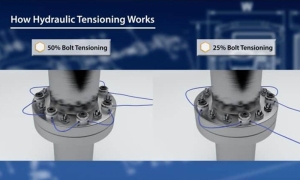

Bolt tensioning, which is a hands-free bolting method, eliminates the disadvantages of torquing by applying load in a different way. Rather than stretching one stud at a time by turning a nut, you can use multiple tensioners at once to stretch studs simultaneously. Once the stud is elongated through tensioning, the nut is turned down using a tommy bar, locking in the desired bolt load. The tensioner then engages in a controlled release, achieving the desired bolt load without turning anything. This process can be used on alternating studs of a flange to achieve 50% bolt tensioning, or on all studs to achieve 100% bolt tensioning. Because the load applied directly to the stud can be measured, bolt tensioning substantially increases bolt load accuracy.

Achieving 50% bolt tensioning, as shown above, significantly reduces crosstalk, increasing accuracy and worker safety. This represents most of the tensioning that EMBARK provides and yields satisfactory results for most bolted joint needs.

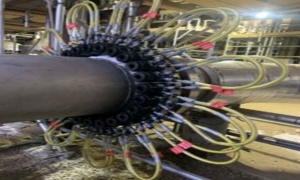

Some bolted joint assemblies require additional speed and complete crosstalk elimination provided by 100% tensioning. Bolt configuration and size can create challenges in achieving 100% tensioning; however, custom tools, such as the EMBARK-designed tools pictured above, can be developed to meet unique tensioning needs.

With bolt tensioning, breakout is achieved by resuming the stretch before removing the nut, eliminating the opportunity for galling, and getting you to discovery work faster. In short, tensioning is safer, more accurate, and faster, resulting in predictable scheduling for your critical path activities during your next turnaround. Faster shutdowns mean fewer workers on hand, reducing labor costs.

Planning Ahead

Preparing for bolt tensioning begins with identifying which flanges would most benefit from shifting from torquing to tensioning. Tensioning is highly recommended for critical flanges which require bolt-load accuracy and zero-leak outcomes. This identification process is best facilitated by your equipment engineer in coordination with tensioning experts, as they can determine criticality and prerequisites (such as those parameters identified earlier, including but not limited to appropriate grip length, flange thickness, and lack of blind holes).

Once the critical flanges have been identified and vetted for tensioning prerequisites, project management plans must be examined to ensure the right materials are on site when they are needed. For example, bolt tensioning requires longer studs than torquing because the tensioner needs more room to grip the stud. Making the shift from torquing to tensioning might necessitate changing applicable hardware to ensure the tensioner has adequate room to grip the stud, which requires consideration when ordering hardware prior to the switch.

Equipment plans must also be examined and adjusted as needed. The logistics for bolt tensioning can be different depending on the location of the flange. While many of the tools used for torquing and tensioning are the same, such as cranes and gang boxes, preparations might be necessary when planning breakouts to allocate the use of such tools.

Finally, labor plans must be considered, and necessary training procured. On-site personnel should familiarize themselves with the bolt tensioning process, appropriate uses, and necessary preparation measures. Working with a tensioning specialist can facilitate this process, helping your team optimize performance.

BOLT TORQUING & TENSIONING SERVICES

EMBARK offers its clients Hydraulic Bolt Torquing and tensioning services, the most familiar technique for the prevention of leaks in bolted assemblies such as pipe flanges. EMBARK uses specially designed equipment, trained manpower, proven bolt-loading calculations, and written procedures to tighten joints to the desired tolerances in a controlled and safe manner. We have our own skilled and trained manpower who can handle such specialized maintenance services.

Hydraulic bolt tensioning is a semi-automated process, substantially more accurate than bolt torquing and delivering a precise residual bolt load. Bolt tensioning enables a hydraulic load, more commonly known as the applied load, to act upon the stud bolt. The effect is like the stretching of a spring, and the stud bolt is elongated.

EMBARK has trained technicians and state-of-the-art equipment for all your bolting needs. Our technicians use the latest equipment and tools available to perform your onsite technical bolting applications. As a qualified service partner, EMBARK provides optimal solutions to the most challenging torque and tension applications. We offer stud tensioning equipment in all sizes and ultrasonic stress measuring for critical flange documentation. When studs are damaged and must be replaced, EMBARK will machine out old studs, preserving the internal threads, if possible, or oversize and rethread the hole, if required. EMBARK's trained technicians provide bolt services in exchangers, manways, valves, fin fan headers, flange to flange, towers, B.O.P.s, pumps, and compressors.

We have a proven track record of managing everything from complex jobs to more standard, day-to-day plant requirements. Put EMBARK's experience to work for you on bolting applications including:

- Broken stud replacement

- Hot bolting

- Standard torque and tensioning applications

- Nut splitting

- Stud removal

- Complete range of box and low-profile wrenches

- Custom reaction arms

- Re-torquing after a shutdown or turnaround

BOLT TORQUING & TENSIONING SERVICES

Torquing is the most used way to achieve fastener preload with bolted joints. Torquing produces this load through rotational force on a nut or bolt head. This torque is usually measured in foot pounds (ft-lbs.) or Newton meters (Nm).

Whether the bolt torque is achieved using a manual 'clicker' torque wrench, pistol grip torque wrench, or hydraulic torque wrench, it is the simplest method of achieving axial load.

The big advantage to torquing is that is typically more cost-effective than tensioning.

However, the skill levels and training of those who use the torque tools equipment are determinants of how successful and accurate torque tightening will be.

Additionally, to achieve a correct torque-tension relationship, the K-factor is critical. (And note, K-factor is NOT the same thing as the coefficient of friction.) A proper K-factor is critical for understanding what applied torque value you will need.

You also need to consider friction on bearing surfaces, bolt diameter, and other variables, which are best examined through experimentation.

As mentioned above, bolt or stud tensioning produces axial load by pulling up on a fastener with what looks like a hydraulic load cell.

To achieve the targeted bolt load, you need to know the area of the tensioner and the amount of force on the fastener, and then adjust the amount of hydraulic pressure.

Hydraulic tensioning began in the 1970s, and in the 50+ years since, tensioning has become more common on specific applications, especially high-pressure flanges with large bolt diameters or critical joints across many industries, including oil and gas, wind, subsea, and power generation.

Because tensioning does not place a twisting force on the fastener as applied torque does, we see tensioners used with long threaded fasteners and on rotating equipment such as reciprocating rods.

Another good use of tensioning is large bolt diameters. On large bolt diameters, tensioning will save you time compared to using hydraulic torque wrenches.

Tensioning is more precise but there are ways torquing can narrow the gap if it is applied correctly.

Torque tools are generally considered accurate within plus or minus 30%. That means if your target were 50 KSI of load, you could see anywhere between 35 KSI and 65 KSI bolt load on your fasteners, and you would be okay with that.

(The difference in bolt load from fastener-to fastener in the flange is known as 'bolt scatter. The lower the bolt scatter, the more consistent the flange assembly.)

With tensioning, you are typically going to see +/- 10% accuracy. That means your bolt scatter will be lower. If the target were 50 KSI, you would see values between 45-55 KSI.

However, there are some important caveats to note here.

First, tensioning is more expensive and more complicated than torquing. So you will need people who have been properly trained in order to properly apply stud tensioning. Torquing, on the other hand, is simple and torque wrenches are readily available in any industrial plant.

Second, torquing can be significantly more accurate than 30% when performed by an appropriately trained assembler, with proper lubrication and with calculations that include a proper (experimentally determined) K-factor. It is not uncommon for well-trained craft assemblers to achieve +/- 15% accuracy or better with torquing.