Mercury Decontamination

Mercury Decontamination

Mercury is a toxic substance that is present in almost every gas or liquid feedstock of oil and gas plants. Mercury can accumulate in plants and pipe systems which can cause significant corrosion. Another problem related to mercury is the possible intoxication of catalysts, like platinum in palladium. In addition, staff can be exposed to the substance during maintenance activities, this should be closely monitored to protect them from potential effects on human health.

EMBARK supplies expertise and guidance in the decontamination of mercury in oil and gas plants. Our experts support clients in detecting, monitoring, and analyzing the production process, measuring mercury emission into the atmosphere, and monitoring of occupational health by the execution of measurements.

Preparations for the decontamination of mercury in oil and gas plant might take some time. EMBARK experts can advise during the process and have broad experience in the environmental guidance of projects where mercury can be a potential threat. Every situation will be unique and EMBARK can prepare a tailored proposal for the approach in cooperation with the client.

Our services include:

- Monitoring of mercury concentrations in process gasses

- Monitoring of mercury concentrations during decontamination of process installations (e.g., during turnarounds or shutdowns)

- Measuring the air emissions to support compliance against permits

- Occupational health measurements

- Monitoring of mercury concentrations in wastewater to support discharge requirements

- Advice with the set-up of online measurements

MERCURY DECONTAMINATION SERVICES

EMBARK provides superior Mercury Decontamination Services and Mercury Screening Services in both private residences and medical and commercial facilities. We have screened homes and decontaminated hundreds of residential, medical, and commercial facilities. In fact, we have successfully decontaminated and remediated more Mercury-contaminated residences, and medical and commercial facilities than any other environmental services firm in the country.

Mercury Decontamination Services are designed to meet indoor air quality standards established by the Environmental Protection Agency (EPA) for the Agency for Toxic Substances & Disease Registry (ATSDR), the National Institute for Occupational Safety and Health (NIOSH), as well as soil and groundwater remediation objectives dictated by the EPA in 40 CFR (from the US Code of Federal Regulations). We approach every project with professionalism and a focus on reducing customer liability.

Mercury is a very challenging substance to collect and clean-up objectives must be extremely conservative and thorough. Mercury Decontamination Services decontaminate and remediate your Mercury problem the first time we clean. By successfully clearing a site after the first attempt, we help you maintain the safest environment possible, avoid potential long-term hazards associated with Mercury contamination, and help you reduce short- and long-term costs.

Types of Mercury Wastes We Collect

EMBARK can collect most metallic Mercury-containing instruments, including meters, manometers, thermometers, and more. We are also able to take care of most of the inorganic Mercury salts and salt solutions, such as mercuric chloride and mercuric sulfate, as well as organic Mercury wastes, such as phenylmercuric acetate. If in small quantities, we can lab pack Mercury waste or put it into drums and profile it as part of a waste stream whatever works best for you and your situation.

Hoplite Testing, Lamex Screening, and Reporting Services

As Mercury is a highly toxic and volatile material, it is important that all testing and screening is done thoroughly and accurately. Our highly effective Hoplite testing process involves our experienced, well-trained staff operating in accordance with NIOSH method 6009. This method requires raising the temperature of the affected area to ensure any minute volumes of mercury will be volatized and captured during the testing process. EMBARK also provides initial Mercury screening with Lamex mercury vapor analyzers demonstrated to be the best available technology and we ensure our fleet of mercury vapor analyzers is calibrated before and after every service event.

When our mercury remediation team is with you on-site, EMBARK project managers keep you continuously informed on the cleanup process, so you know exactly how long the area will be off-limits and what additional remedial actions may be required. EMBARK personnel undergo hundreds of hours of apprenticeship in a classroom setting as well as in the field before they are qualified to become mercury remediation, project managers. Upon successful project completion, EMBARK can provide comprehensive reporting services to help you ensure compliance with all local, state, and federal regulatory agencies.

MERCURY DECONTAMINATION SERVICES

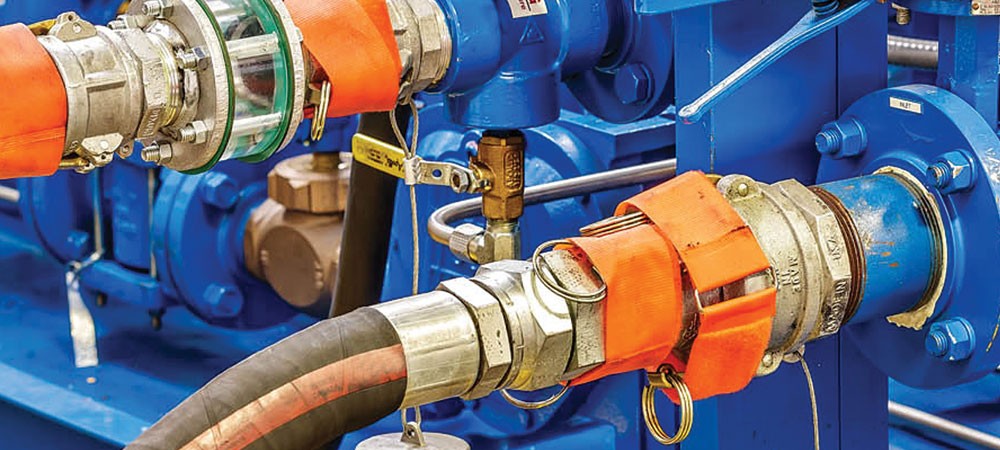

We satisfy these demands by applying the latest equipment and technology with our multi-skilled specialists to meet and exceed rising environmental, availability, and efficiency requirements in a timely and cost-effective way. Our mechanical services are uniquely developed to cater to projects of all sizes, and we are one of the few companies capable of delivering simultaneous shutdowns in multiple countries. Being one of the first to adopt a blind-to-blind approach, we offer a range of general mechanical services that includes fabrication, on-site modification, stainless steel welding (inert and normal atmospheres), vessel blinding, column cleaning, replacement of trays/internals, on-site machining (flange facing, bed milling, valve lapping services), flange management, controlled bolting, and online leak sealing. In addition, we incorporate the pre-engineering essentials of estimating, planning, scheduling, and task team orientation.

MAIN SERVICES INCLUDE

- Mercury sampling, analysis, and mapping studies

- Mercury decontamination (process systems & equipment) including sludge removal

- Pipeline chemical pigging, flushing, and decontamination

- Mercury area and personnel occupational exposure monitoring

- Mercury scale, sludge, waste minimization and management (TLE)

- Mercury mapping studies for pipeline systems, process platforms, natural gas plants, NGL plants, LNG process trains, and refineries

- Plant shutdown monitoring (steam-out, purging, vessel opening)

- Production platform mercury decontamination

- Cryogenic heat transfer equipment inspection & modeling

- Mercury removal unit adsorbent handling services including unloading, loading, and replacement (TLE)

- Pipeline abandonment programs (special programs for mercury decontamination)

MERCURY DECONTAMINATION SERVICES

Throughout the oil and gas industry, the impact of mercury in produced hydrocarbons is an emergent issue. This is not only the case for unconventional resource plays but also for conventional plays as they near the end of their economic production and as process systems require decommissioning. Produced mercury ultimately contaminates hydrocarbon processing equipment and transportation systems like those found on offshore production platforms, offshore gathering platforms, or subsea pipelines.

The dismantling, removal, and disposal of these systems present unique challenges and risks to decommissioning personnel and to marine ecosystems. Global conventions provide guidance for decommissioning of oil and gas facilities in international waters, but specific regulations about residual mercury concentrations in production systems (either as scale or complexed in the grain boundary of metals) are not currently available.

Mercury adsorbs and chemisorbs to carbon steel surfaces, primarily through amalgamation and diffusion into the scale, making carbon and stainless steel excellent mercury scavengers. Fortunately, this process is somewhat reversible depending on many factors.

However, mercury complexed and incorporated into steel surfaces is not easily affected by typical hydrocarbon chemical decontamination chemistries and methods. The research group at PEI has concentrated efforts on understanding the sorption dynamics of mercury in steel pipes and in the development of effective chemical decontamination solutions. Pilot studies based on steel coupon samples from impacted pipelines are a key component of evaluating mercury decontamination methods and identifying the most cost-effective technology for application to mercury-impacted pipelines.

Oil and gas companies across the globe are faced with significant decommissioning challenges, including operations in the Gulf of Thailand and the Gulf of Mexico (GOM). Particular attention should be considered in decommissioning strategies for process systems previously or currently exposed to mercury-contaminated hydrocarbon streams. Two key considerations required for the development of safe decommissioning strategies (including decontamination) are:

1) an understanding of the nature and distribution of mercury along with depth profiles in pipelines and process equipment

2) consideration of mercury decontamination goals.